Liquid Filling

-

-

앰플 충전기

· 어떠한 규격의 AMPOULE도 쓰러짐이 없는 CONVEYOR SYSTEM

· SERVO CONTROL 충전으로 정확한 충전

· 충전 후 깔끔한 용봉처리

· 충전 전/후 질소충전 가능

· CHANGE PARTS의 교환이 간단함(특수공구 필요없음)

· 사용자 편의를 위한 TOUCH SCREEN HMI SYSTEM(PC 기반 TOUCH 적용)

· cGMP 및 21 CFR PART 11 적용

-

01Feeding

-

02Filling

-

03Closing

※ 표를 좌우로 슬라이드하여 이용하세요.

Specifications

| DESCRIPTION | MODEL | |

|---|---|---|

| DAF-3000 | ||

| Machine Type | LINE-TYPE | |

| Out Capacity | 1ml [Ø10 | 360~380 EA/min |

| 2ml [Ø11.2] | ||

| Filling Method | Servo Contro | |

| Rotary Slide Dosing Pump | 8 PCS | |

| Filling Nozzle | 8 PCS | |

| N2 Nozzle (충전 전/후) | 16 PCS | |

| Electricity Consumption | Standard Voltage | 220/380V, 50/60Hz |

| Installed Power | 7kW | |

| COMPRESSED AIR | Pressure | 3~5Kg/㎠ |

| Consumption | 14ℓ/min | |

| Drive Speed Contro | Inverter Control | |

| Electric Control System | PLC for Monitoring | |

| Dimension | (L)3,980 X (W)2,060 X (H)2,100 mm | |

| Weight | 2,500kg | |

-

-

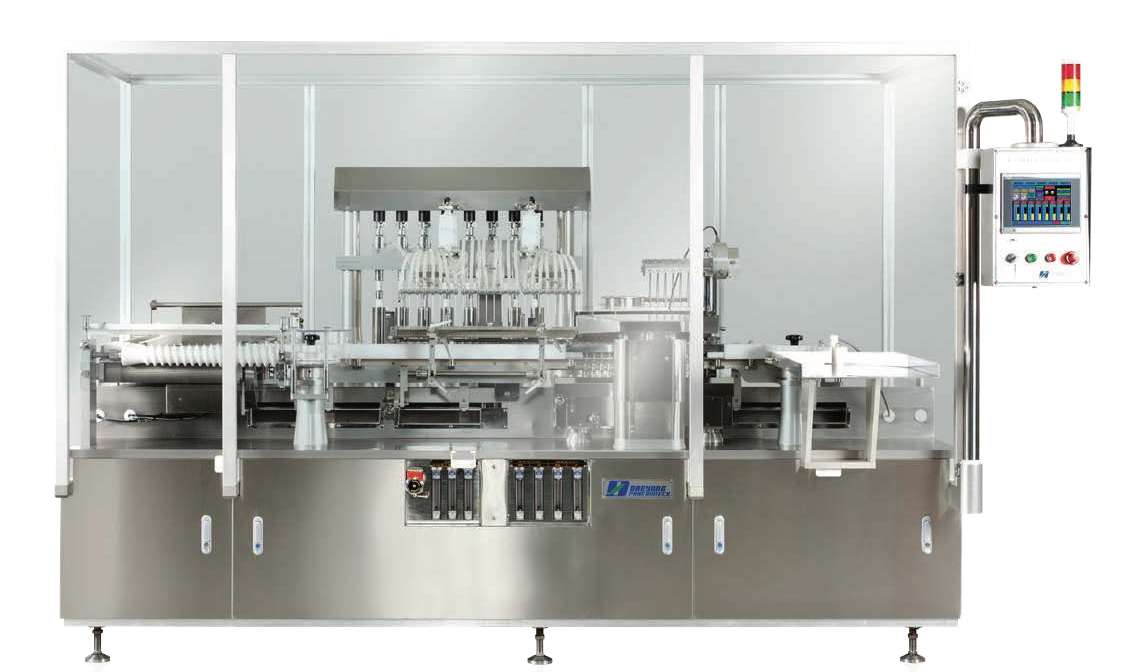

바이알 액상충전기

· LINE TYPE과 ROTARY TYPE등 다양한 모델 보유

· 특수 제작 노즐로 충전액 맺힘현상 없음

· SERVO CONTROL 충전방식으로 정확한 충전

· PROGRAM에 의한 용이한 충전량 설정 및 조정

· NO VIAL - NO FILLING

· 충전 전/후 질소충전 가능

· CHANGE PARTS의 교환이 간단함(특수공구 필요없음)

· CIP/SIP 적용가능(GLOBAL PUMP MAKER 펌프 적용 - SPC, NEOCERAMIC)

· IPC SYSTEM 적용가능(SAMPLING WEIGHT CHECK, 100% WEIGHT CHECK)

· METTLER TOLEDO사 고정밀 저울 적용

· 사용자 편의를 위한 TOUCH SCREEN HMI SYSTEM(PC 기반 TOUCH 적용)

· cGMP 및 21 CFR PART 11 적용

-

01Feeding

-

02Rubber stoppering

-

03Service tank & Pump station

※ 표를 좌우로 슬라이드하여 이용하세요.

Specifications

L TYPE (Line type)

| DESCRIPTION | MODEL | ||||

|---|---|---|---|---|---|

| DLF-1000L | DLF-2000L | DLF-3000L | DLF-4000L | ||

| Machine Type | LINE TYPE (연속식) | LINE TYPE (연속식) | LINE TYPE (연속식) | LINE TYPE (연속식) | |

| Out Capacity | 10ml [Ø22] | 80~100 Vial/min | 180~200 Vial/min | 280~300 Vial/min | 380~400 Vial/min |

| Filling Method | Servo Contro | ||||

| Rotary Slide Dosing Pump | 4 PCS | 6 PCS | 8 PCS | 10 PCS | |

| Filling Nozzle | 4 PCS | 6 PCS | 8 PCS | 10 PCS | |

| Nitrogen Nozzle | 4 PCS | 6 PCS | 8 PCS | 10 PCS | |

| Electricity Consumption |

Standard Voltage | 220/380V, 50/60Hz | |||

| Installed Power | 7kW | 8kW | 9kW | 10kW | |

| COMPRESSED AIR |

Pressure | 5Kg/㎠ | |||

| Consumption | 14ℓ/min | ||||

| Drive Speed Control | Inverter Control | ||||

| Electric Control System | PLC & Touch Screen | ||||

| Dimension | (L)2,620 X (W)1,500 X (H)1,800 mm |

(L)2,800 X (W)1,600 X (H)1,800 mm |

(L)2,800 X (W)1,700 X (H)1,800 mm |

(L)2,800 X (W)1,800 X (H)1,800 mm |

|

| Weight | 2,500kg | 2,600kg | 2,700kg | 2,800kg | |

R TYPE (Rotary type)

| DESCRIPTION | MODEL | ||||

|---|---|---|---|---|---|

| DLF-1000L | DLF-2000L | DLF-3000L | DLF-4000L | ||

| Machine Type | Rotary TYPE (연속식) | Rotary TYPE (연속식)) | Rotary TYPE (연속식) | Rotary TYPE (연속식) | |

| Out Capacity | 10ml [Ø22] | 80~100 Vial/min | 180~200 Vial/min | 280~300 Vial/min | 380~400 Vial/min |

| Filling Method | Servo Contro | ||||

| Rotary Slide Dosing Pump | 4 PCS | 6 PCS | 8 PCS | 10 PCS | |

| Filling Nozzle | 4 PCS | 6 PCS | 8 PCS | 10 PCS | |

| Nitrogen Nozzle | 4 PCS | 6 PCS | 8 PCS | 10 PCS | |

| Electricity Consumption |

Standard Voltage | 220/380V, 50/60Hz | |||

| Installed Power | 7kW | 8kW | 9kW | 10kW | |

| COMPRESSED AIR |

Pressure | 5Kg/㎠ | |||

| Consumption | 14ℓ/min | ||||

| Drive Speed Control | Inverter Control | ||||

| Electric Control System | PLC & Touch Screen | ||||

| Dimension | (L)1,600 X (W)1,000 X (H)1,800 mm |

(L)2,000 X (W)1,200 X (H)1,800 mm |

(L)1,400 X (W)1,800 X (H)1,800 mm |

(L)1,600 X (W)1,800 X (H)1,800 mm |

|

| Weight | 2,000kg | 2,100kg | 2,200kg | 2,300kg | |